GenCell Rex – Utility Backup Power Solution

The Power Challenge

As electrical grids age and extreme weather events become more frequent, ensuring power resilience for always-connected businesses and consumers is increasingly critical. With thousands of reported outages and significant economic costs, the need for reliable backup power solutions has never been more evident.

GenCell REX™: Enhanced Backup Power with Extended Runtime

Powered by hydrogen, GenCell REX™ provides a robust utility backup power solution, producing 5kW of emission-free electricity for substations during outages of any duration. Here’s how it revolutionizes backup power:

- Extended Runtime: Unlike legacy backup battery systems that offer only 6-8 hours of electricity, GenCell REX™ provides continuous power to keep circuit breaker auto-reclosers operational until the grid recovers.

- Cost Savings: By eliminating the need for multiple battery rooms and avoiding the pollution and maintenance costs associated with diesel, GenCell REX™ offers significant cost savings over its lifecycle.

- Resilient Design: The solution includes a shelter enclosure resistant to high-voltage interference and earthquakes, ensuring the durability and reliability of all system components.

Key Features:

- 5kW Fuel Cell Generator: Efficiently produces electricity using hydrogen, ensuring reliable backup power for substations.

- Heat Utilization Unit: Dissipates excess heat generated during operation, optimizing system efficiency and reliability.

- Energy Bridge: Instantly generates electrical power and regulates output to match demand, ensuring uninterrupted power supply.

- Fuel Supply: Utilizes standard hydrogen cylinders for convenient and reliable fuel storage.

- Shelter Enclosure: Protects all system components from environmental elements, ensuring long-term durability and performance.

TECHNICAL SPECIFICATIONS

| PERFORMANCE | |

| Rated power configuration | 5kW |

| Output voltage configurations | -48 VDC / +VDC / 230 VAC / 130 VDC |

| Emissions | Usable heat, water vapor |

| FUEL | |

| Hydrogen | 99.95% or higher |

| Fuel consumption | 70 g/kWh |

| Input pressure | 300-500 kPa |

| Storage | Internal. Up to 6 standard hydrogen cylinders |

| ELECTROLYTE | |

| Potassium hydroxide | 28-32% mass |

| OPERATION | |

| Startup Time | Immediate – w/ Energy Bridge |

| Automatic Start/stop | Available |

| Installation | Outdoor |

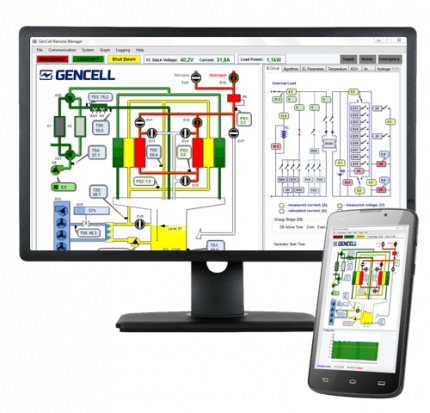

| Remote control/management (NOC) | Available |

| MAINTENANCE | |

| Every 500 hours of operation or annually, whichever comes first | |

| PHYSICAL | |

| Footprint | 2,800 x 2,250 x 2,500 mm (110.2 x 88.6 x 98.4 in.) |

| NORMAL OPERATION CONDITIONS | |

| Operating temperature | -20 o C up to +45 o C (- 4 o F up to +113 o F) |

| Relative humidity | Up to 90% |

| Storage temperature | -40 o C up to +55 o C (-40 o F up to +131 o F) |

| CERTIFICATION | |

| IEC/EN 62282-3-100, IEC 60950-1, IEC 60204-1,

IEC 60335-1, EN 61000-6-2, EN55011 IEEE693-2005 (Seismic, High Performance Level), OSHA1910. 103, IEEE Std C37 .90. 1-2012 Sections 4. 1/4.2 EMC: EN55011/EN61000-6-2 ISO 9001:2015 IEEE 693 (Seismic design) |

Reviews

There are no reviews yet.