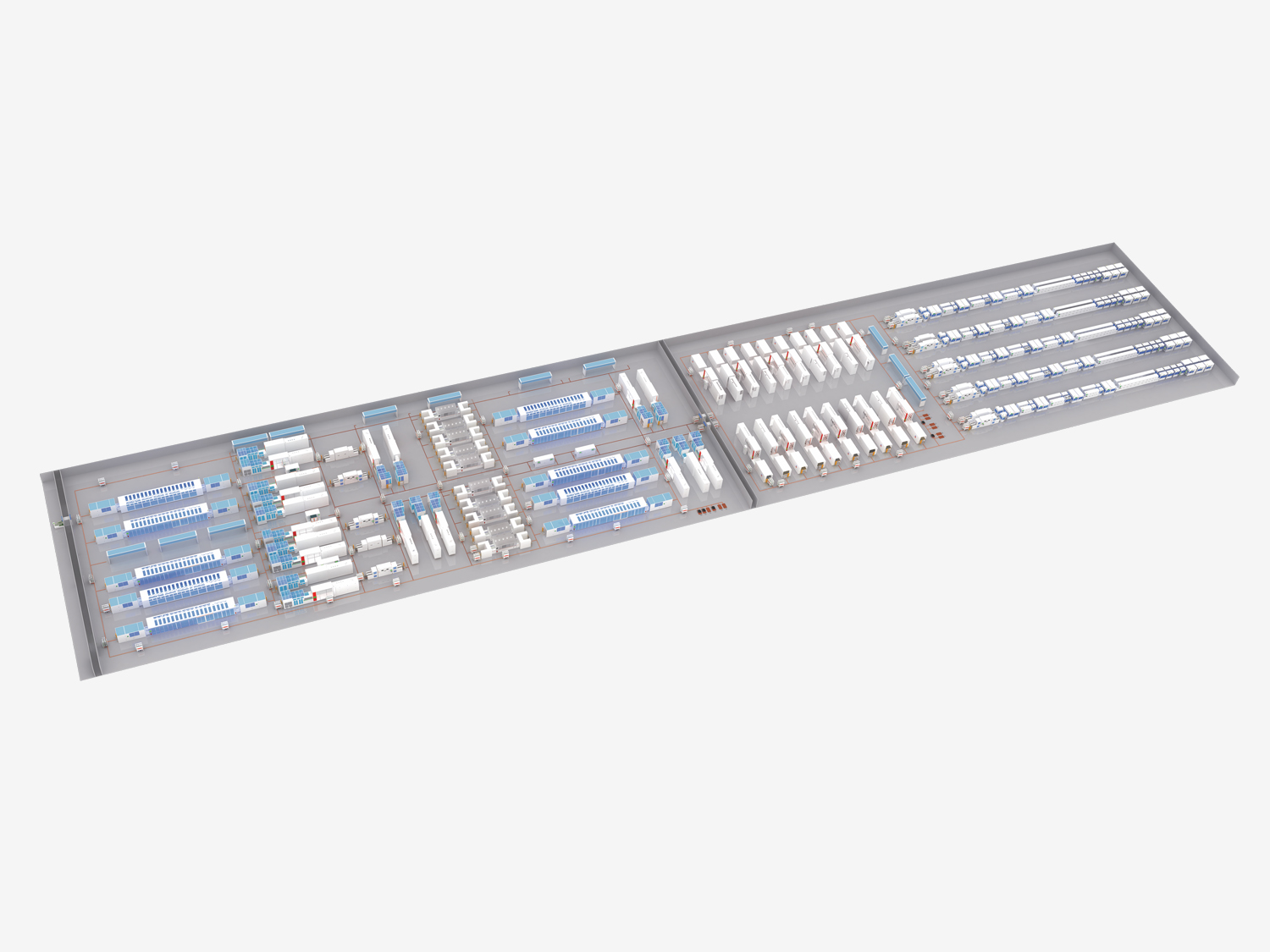

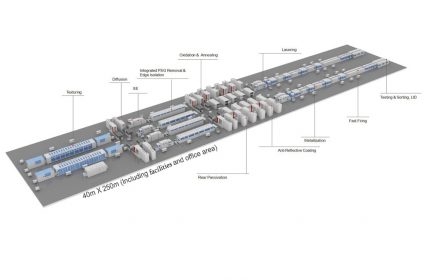

Automatic Intelligent Factory

In the era of Industry 4.0, the Automatic Intelligent Factory represents the pinnacle of technological advancement in manufacturing. By integrating cutting-edge automation, intelligent control systems, and seamless data interaction, this innovative concept revolutionizes traditional production processes, paving the way for unprecedented efficiency, productivity, and flexibility.

Equipment Application:

The Automatic Intelligent Factory is designed to replace manual transportation of cassettes, enabling intelligent interaction of all information and resource control. It facilitates automatic production across the entire production line and intelligent management of the entire plant.

Features:

- Latent-Type AGV + Shelf Delivery System: Utilizing a sophisticated delivery system consisting of “latent-type AGV + shelf,” the factory seamlessly transports cassettes between each process step, from the raw material warehouse to the finished products warehouse.

- Customized Task Scheduling System: The factory employs a customized MCS task scheduling system, integrated with the MES system, to control the RCS vehicle scheduling system. This ensures unmanned smart production, optimizing workflow efficiency.

- Mechanical Connection with Tool Automation: The cassette shelf mechanically connects with the tool automation structure, enhancing the reliability of cassette transportation. Program transfer is facilitated using a network cable, ensuring seamless communication.

- First-In-First-Out Principle: By using cassette shelves to replace buffer stations, the factory adheres to the first-in-first-out principle, ensuring optimal material flow while significantly reducing costs.

- Proven AGV Suppliers: Partnering with renowned AGV suppliers known for their proven scheduling systems, the factory ensures reliable and efficient transportation of cassettes.

- Advanced Navigation Systems: The factory employs texture navigation and laser SLAM navigation technologies, ensuring precise navigation and maneuverability in complex environments.

- Fast Battery Swap: With a fast battery swap mechanism, the factory improves the utilization ratio of AGV vehicles, minimizing downtime and maximizing operational efficiency.

Parameters:

- Name: Smart Factory

- Applicable: Crystalline solar cell production line

- AGV Navigation Method: Texture navigation, laser SLAM navigation

- AGV Cassette Handling Amount: Equal to or greater than [pcs] cassettes

- Operate Mode: Automatic

Benefits:

- Enhanced Efficiency: The Automatic Intelligent Factory streamlines production processes, reducing manual intervention and optimizing workflow efficiency, leading to increased productivity and throughput.

- Improved Accuracy: By utilizing advanced navigation systems and intelligent control algorithms, the factory ensures precise and accurate transportation of cassettes, minimizing errors and improving quality.

- Cost Savings: Through the elimination of manual labor, reduction of material waste, and optimization of resource utilization, the factory achieves significant cost savings over time, enhancing overall profitability.

- Flexibility and Adaptability: With its intelligent control systems and modular design, the factory offers unparalleled flexibility and adaptability to changing production demands, enabling rapid adjustments and reconfigurations as needed.

- Safety and Reliability: By automating repetitive and hazardous tasks, the factory enhances workplace safety and reliability, reducing the risk of accidents and ensuring consistent performance.

Reviews

There are no reviews yet.