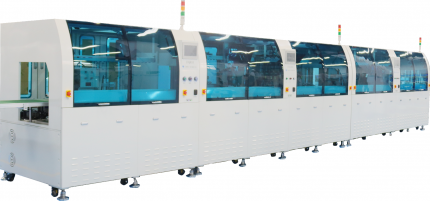

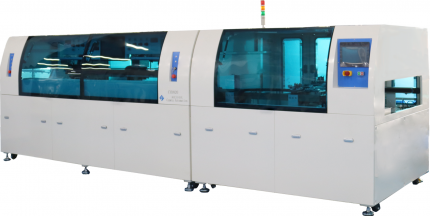

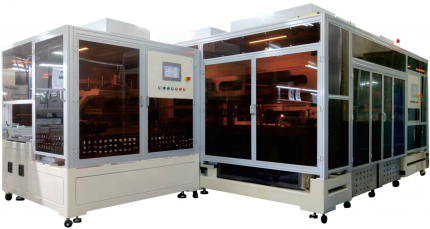

Automatic backlight, laminated all-in-one machine backlight board assembly equipment

Streamline your manufacturing process with our CYB680 and CYB780 automatic assembly equipment designed for LCD and backlight assembly. These machines offer seamless automation for efficient production of LCD and backlight assemblies ranging from 5 to 17.3 inches.

CYB680 Automatic Assembly Equipment:

- Main Function: LCD and backlight automatic assembly machine, capable of automatic equipment loading, unloading, TPC, and Mylar light source automatic installation for terminal type 5-17.3 inch LCD and backlight assemblies.

- Machine Vision Configuration: Equipped with backlit camera (4 cameras), LCD camera (2 cameras), and inspection camera (2 cameras) for precise assembly and quality control.

CYB780 Automatic Assembly Equipment:

- Main Function: Backlight and panel automatic feeding, visual alignment, assembly, pressure retention, intermittent inspection, and automatic unloading for 5-17.3 inch LCD with backlight assemblies.

- Machine Vision Configuration: Features backlit camera (4 cameras), LCD camera (4 cameras), and inspection camera (8 cameras) for accurate alignment and thorough inspection.

Equipment Features:

- LCD/BLU Automatic Loader Compatibility: Can be equipped with LCD/BLU automatic loader for enhanced efficiency in loading components.

- One-Button Cutter Function: Machine vision with one-button cutter function ensures precise cutting for optimal assembly results.

- High Assembly Accuracy and Efficiency: Offers high assembly accuracy and efficiency characteristics, ensuring superior quality and productivity.

- CIM Communication System Compatibility: Can be equipped with CIM communication system and code reading equipment for easy data acquisition and management.

Upgrade your manufacturing process with our Automatic Backlight Laminated All-in-One Machine Backlight Board Assembly Equipment. Experience enhanced efficiency, accuracy, and productivity in LCD and backlight assembly.

Reviews

There are no reviews yet.