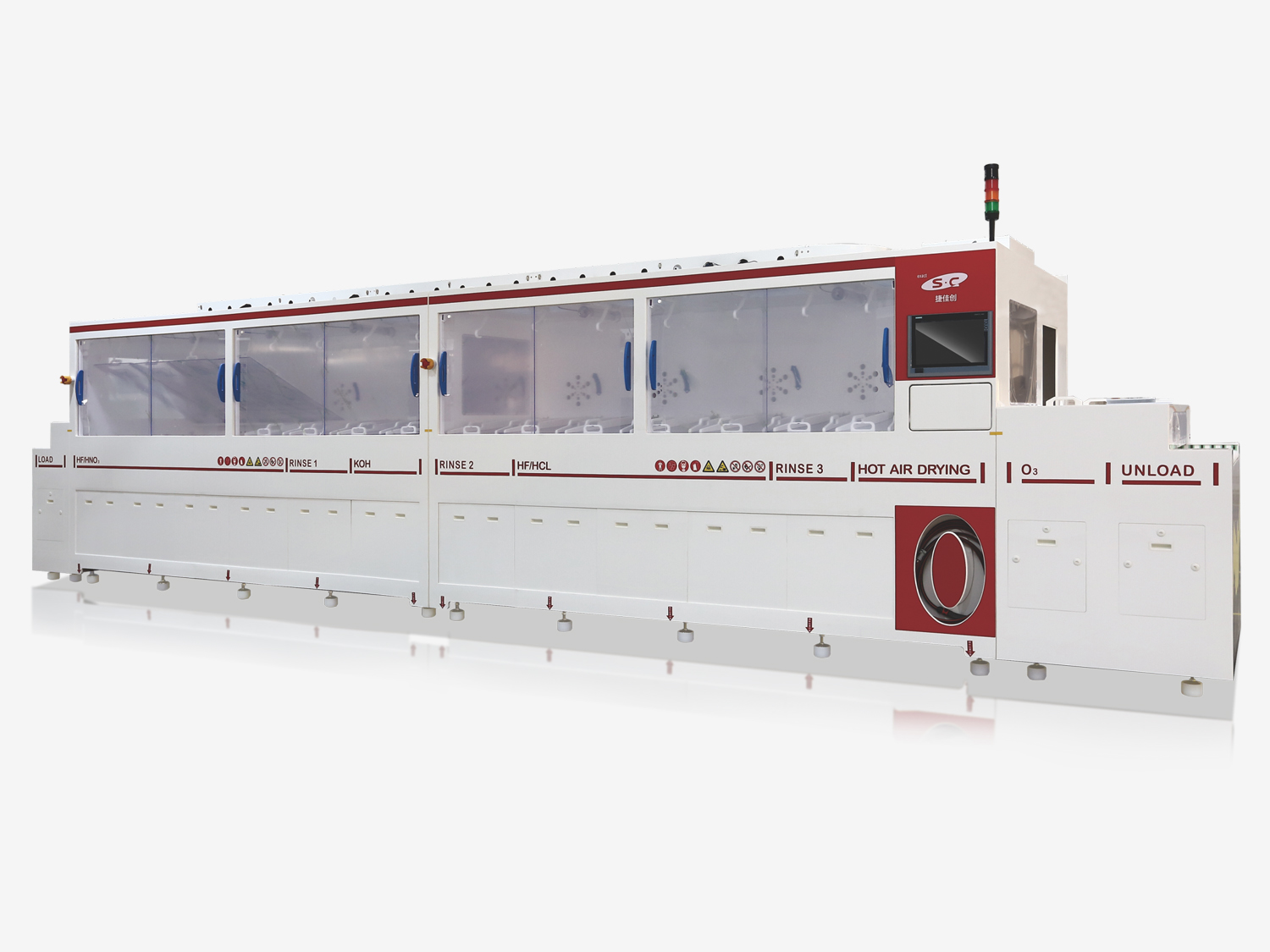

Inline Acid Polishing Equipment

Equipment Application

The Inline Acid Polishing Equipment is specifically designed for the etching/polishing, cleaning, and drying of both single and polycrystalline silicon wafers, playing a crucial role in the production process of solar cells.

Process Flow:

- Front Protection

- Etching/Polishing

- Alkaline Cleaning

- Pickling

- Drying

- Water Layer Protection (for SC-LSP8000)

- Etching/Polishing (for SC-LSP8000)

- Alkaline Cleaning (for SC-LSP8000)

- Acid Cleaning (for SC-LSP8000)

- Drying (for SC-LSP8000)

Technical Features:

- High Capacity: The equipment offers high throughput with options for 5 lanes at 4500pcs/hour or 10 lanes at 8000pcs/hour, ensuring efficient processing of silicon wafers.

- Uniformity and Long Liquid Life: It provides excellent uniformity in processing and maintains a long bath life, contributing to consistent and reliable results over time.

- Additive Compatibility: The equipment supports multiple additive or mixed additive technologies, offering flexibility in processing requirements and optimization.

- Handling Capability: Capable of handling silicon wafers as thin as 120μm, ensuring compatibility with a wide range of wafer thicknesses.

- Quick Liquid Change: Allows for quick inline bath changes, reducing downtime and optimizing production efficiency.

- Backside Polishing and Low Drug Consumption: Supports backside polishing processes while maintaining ultra-low chemical consumption, minimizing waste and cost.

- MES Integration: Compatible with Manufacturing Execution Systems (MES), offering seamless integration into production environments, with optional online weighing detection for added quality control.

- Acid Polishing Function: Compatible with acid polish functions, providing additional versatility and capability in processing requirements.

Benefits of Inline Acid Polishing Equipment

- High Efficiency: With the capacity to process up to 4500pcs/hour in a 5-lane configuration and 8000pcs/hour in a 10-lane setup, the equipment significantly enhances production efficiency, leading to increased throughput and reduced processing time.

- Uniform Results: The equipment ensures high uniformity in etching/polishing, cleaning, and drying processes, guaranteeing consistent quality across all processed silicon wafers or solar cells.

- Extended Bath Life: Featuring long liquid life, the equipment minimizes the frequency of liquid replenishment and replacement, reducing operational costs and downtime associated with maintenance.

- Versatile Additive Support: Supporting multiple additive or mixed additive technologies, the equipment offers flexibility in process customization, allowing for the optimization of etching and cleaning solutions based on specific requirements.

- Handling Thin Wafers: With the capability to handle wafer thicknesses as thin as 120μm, the equipment accommodates the processing needs of increasingly thinner silicon wafers without compromising quality or efficiency.

- Quick Liquid Changeover: The ability to quickly change liquids and perform online liquid changes streamlines operations, minimizing downtime between different processing stages and ensuring continuous production flow.

- Backside Polishing Support: Supporting backside polishing processes with ultra-low drug consumption, the equipment enhances the efficiency and effectiveness of polishing operations while minimizing chemical usage.

- Integration with Manufacturing Systems: Compatibility with Manufacturing Execution Systems (MES) facilitates seamless integration into production lines, allowing for enhanced process monitoring, data management, and workflow optimization. Additionally, optional online weighing detection provides further quality control capabilities, ensuring adherence to production standards.

- Acid Polishing Compatibility: The equipment’s compatibility with acid polishing functions expands its versatility, allowing for additional processing capabilities to meet diverse manufacturing needs.

Reviews

There are no reviews yet.