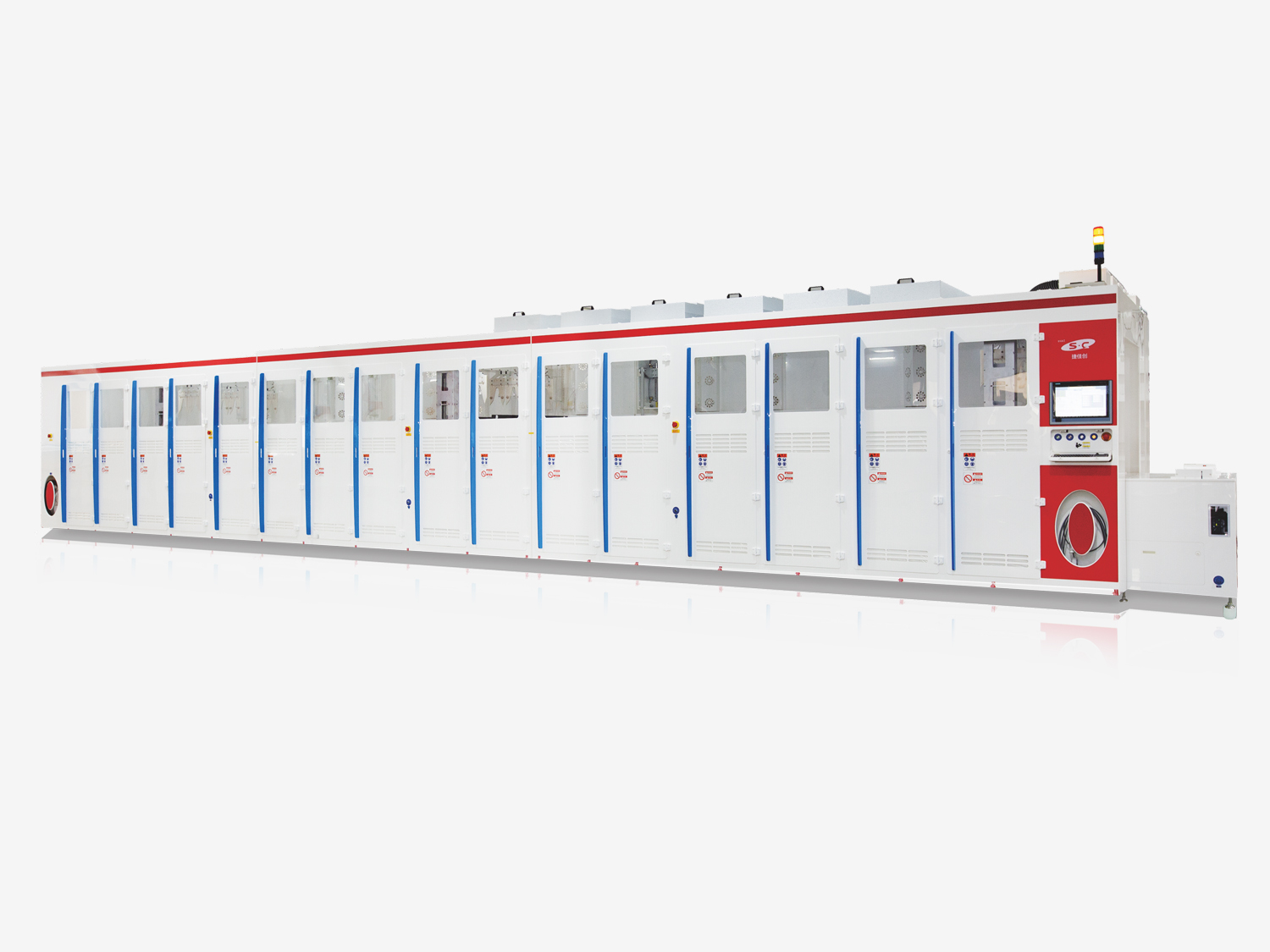

Trough Alkali Polishing Cleaning Equipment

Equipment Application:

This cutting-edge equipment is meticulously designed for the precise polishing, etching, and cleaning of silicon wafers following the diffusion process. Its versatility extends to facilitating backside texturing and cleaning of double-sided cells, ensuring optimal performance in solar cell manufacturing processes.

Process Flow:

- Pre-cleaning

- Polishing

- Post-cleaning or O3 cleaning

- Pickling

- Pre-dehydration

- Drying (for reference)

Technical Features:

- Capacity: With a capacity of 400 pieces per batch and an impressive throughput of 8000 pieces per hour, it ensures high efficiency and productivity.

- Versatility: The equipment is adept at accommodating backside etching and polishing, along with single-crystal backside texturing processes, catering to diverse manufacturing needs.

- Adaptability: It supports a range of additive technologies, offering flexibility in the manufacturing process to meet specific requirements.

- Handling Capability: The equipment can handle silicon wafers with a thickness as thin as 120μm, enabling precision manufacturing even with delicate materials.

- Cleanliness: Featuring a dry clean area and a self-cleaning system, it maintains optimal cleanliness standards, crucial for ensuring product quality.

- Fluid Management: Its quick fluid change and online fluid change capabilities streamline operations, minimizing downtime and maximizing efficiency.

- Integration: It seamlessly integrates with Manufacturing Execution Systems (MES), Radio-frequency identification (RFID) systems, and offers an optional online weighing function, providing comprehensive control and monitoring capabilities throughout the manufacturing process.

Benefits of Trough Alkali Polishing Cleaning Equipment

- Enhanced Productivity: With a high throughput of 8000 pieces per hour, the equipment significantly boosts manufacturing efficiency, allowing for larger production volumes within shorter time frames.

- Improved Quality: The precise polishing, etching, and cleaning processes ensure consistent and uniform results, leading to higher quality silicon wafers and solar cells with reduced defects.

- Versatility: Its compatibility with various additive technologies and processes such as backside etching and texturing enables manufacturers to adapt to evolving industry standards and customer demands easily.

- Cost Efficiency: The equipment’s efficient fluid management system and quick fluid change capabilities minimize wastage and reduce operational costs associated with consumables, contributing to overall cost savings.

- Increased Yield: By handling silicon wafers as thin as 120μm with precision, the equipment minimizes material wastage and enhances yield rates, maximizing the return on investment for manufacturers.

- Streamlined Operations: Integration with MES and RFID systems streamlines workflow management and data tracking, facilitating better decision-making, and process optimization.

- Reduced Downtime: The equipment’s self-cleaning system and online fluid change capabilities minimize maintenance downtime, ensuring continuous operation and maximizing uptime for production.

Reviews

There are no reviews yet.