Automatic Wafer Handling System for PECVD

Equipment Application

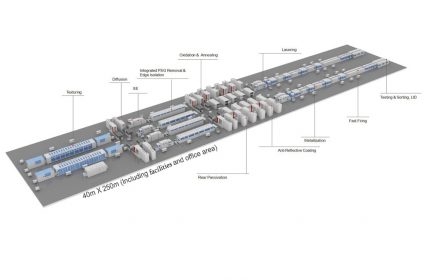

The SMZ-IV Automatic Wafer Handling System for PECVD is designed for online integration with one or two boat-boat interface PECVD equipment. It facilitates the automatic transfer of graphite boats and the loading and unloading of silicon wafers. This system streamlines the transportation of wafers from cassettes to graphite boats and vice versa, optimizing the efficiency of PECVD processes.

Technical Features:

- Modular Design: The equipment is modularly designed, allowing for online connection with one or two sets of PECVD equipment. This modular design enhances flexibility and scalability to adapt to varying production requirements.

- User-Friendly Control: Controlled by a PC, the system features menu operation via a tablet computer interface, offering simplicity and clarity in operation. This intuitive control interface enhances ease of use and ensures efficient operation.

- Advanced Detection Functions: The system is equipped with various online detection functions, including micro-crack detection, film thickness detection, color inspection, CCD wafer warpage detection, and automatic processing of defective wafers (optional function at additional cost). These detection capabilities ensure quality control and enhance process reliability.

- Online/Offline Configuration: The system offers both online and offline configuration options, providing flexibility to adapt to different production setups and workflows.

- Integration with Advanced Technologies: Compatible with Automated Guided Vehicles (AGV), Radio-frequency identification (RFID) systems, and optional Manufacturing Execution System (MES) functions, the system can be seamlessly integrated into advanced manufacturing environments. This integration enhances automation, data tracking, and overall process efficiency.

Benefits of Automatic Wafer Handling System for PECVD (SMZ-IV)

- Enhanced Efficiency: By automating the transfer of graphite boats and the loading/unloading of silicon wafers, the system significantly improves efficiency in PECVD processes. This automation reduces manual labor requirements and minimizes handling time, leading to increased throughput and overall productivity.

- Flexible Modular Design: The modular design of the equipment allows for online connection with one or two sets of PECVD equipment. This flexibility enables seamless integration into existing production lines and facilitates scalability to accommodate varying production demands.

- User-Friendly Operation: Controlled via a PC with a simple and clear menu operation on a tablet computer interface, the system is easy to operate and requires minimal training. This user-friendly design enhances operator efficiency and reduces the likelihood of errors during operation.

- Advanced Detection Capabilities: With online detection functions for micro-cracks, film thickness, color differences, and wafer warpage, the system ensures quality control and detects defects in real-time. This proactive approach to quality assurance minimizes the production of defective wafers, reducing material waste and enhancing yield rates.

- Online/Offline Configuration Options: Offering both online and offline configuration options, the system provides flexibility to adapt to different production setups and workflows. This versatility allows for seamless integration into various manufacturing environments and facilitates efficient operation.

- Integration with Advanced Technologies: Compatible with AGV, RFID systems, and optional MES functions, the system can be integrated with advanced manufacturing technologies for enhanced automation and data tracking. This integration streamlines production processes, improves traceability, and enables better decision-making based on real-time data.

- Improved Process Reliability: With the ability to automatically process defective wafers (optional function), the system enhances process reliability by promptly addressing issues as they arise. This feature reduces the likelihood of production delays and ensures consistent quality output.

- Cost Savings: Through increased efficiency, reduced material waste, and improved yield rates, the system helps minimize production costs and optimize overall operational expenses. Additionally, its modular design allows for future expansion and upgrades, protecting the investment over the long term.

Reviews

There are no reviews yet.