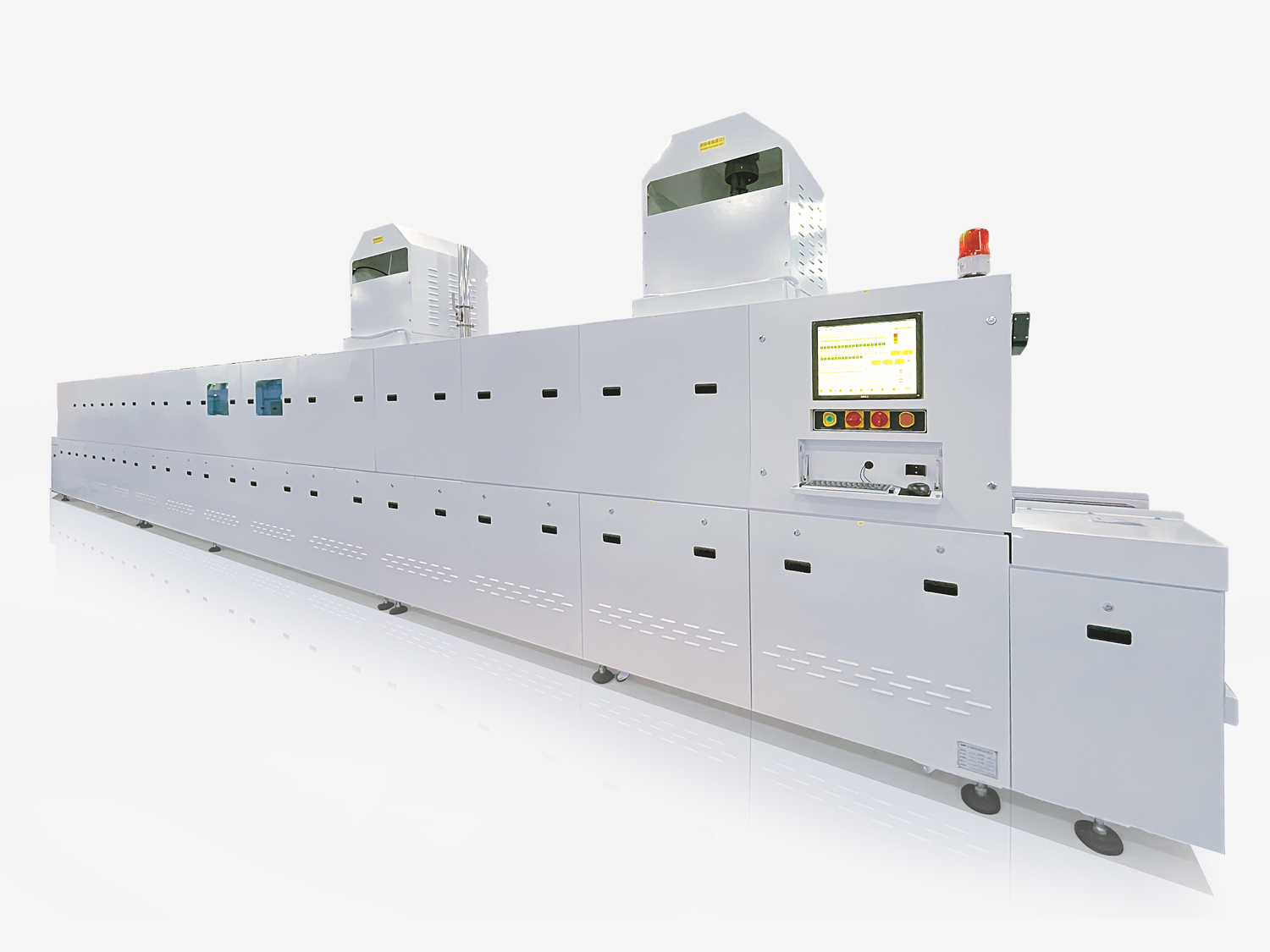

Mesh chain sintering furnace

Equipment Application:

The firing furnace with mesh-belt conveyor is designed for smelting the printed front and rear electrodes onto the PN junction layer. This process forms an ohmic contact, enabling the electrical energy collected by the thin grid lines of the cell to flow out through the main grid lines. It plays a crucial role in the production of solar cells, ensuring efficient energy conversion.

Process Flow:

The process flow of the firing furnace typically includes drying, pre-sintering, main sintering, and cooling stages. During drying, moisture is removed from the electrodes to prepare them for sintering. Pre-sintering involves heating the electrodes to a specific temperature to initiate the sintering process. Main sintering is where the electrodes are heated to the required temperature for the sintering reaction to occur effectively. Finally, cooling helps to stabilize the sintered electrodes and prevent thermal shock.

Technical Features:

- Dual-Track Production Line: The furnace features a double-track production line, allowing for independent operation of electrical racks without interference.

- Fast Cycle Time (CT): With a cycle time of ≤0.95s, the furnace ensures efficient processing of electrodes, optimizing production throughput.

- High Production Capacity: The furnace boasts a large production capacity, with an actual throughput of up to 175,000 pieces per day. This high throughput enables mass production of solar cells to meet market demand.

- High-Quality Wafers: Utilizing A-grade wafers, the furnace maintains a low mono breakage rate of 0.03%, ensuring consistent quality and reliability in the manufactured solar cells.

Benefits:

- Enhanced Efficiency: The mesh-chain sintering furnace streamlines the process of forming ohmic contacts on solar cell electrodes, resulting in enhanced efficiency in energy conversion. By ensuring proper smelting and sintering of electrodes, it optimizes the performance of solar cells, contributing to higher overall efficiency.

- Increased Production Capacity: With its high throughput capability, the furnace significantly boosts production capacity, allowing for the rapid manufacturing of solar cells. This increased output helps meet market demand and supports the scaling of solar energy production.

- Improved Quality Control: The furnace facilitates precise control over the sintering process, ensuring uniform heating and sintering of electrodes. This results in consistent product quality, minimizing variations and defects in the manufactured solar cells.

- Cost Efficiency: By automating the smelting and sintering process, the furnace reduces manual labor requirements and operational costs associated with production. Its high-speed operation and large capacity contribute to cost efficiency by maximizing output while minimizing energy consumption.

- Enhanced Reliability: With its advanced design and robust construction, the furnace offers reliability and durability in operation. It is engineered to withstand continuous use in industrial settings, ensuring uninterrupted production and minimal downtime.

- Compliance and Certification: The furnace complies with industry standards and regulations, ensuring adherence to quality and safety requirements. It may also be certified by relevant authorities, providing assurance of its performance and reliability.

- Environmental Benefits: By facilitating the mass production of solar cells, the furnace promotes the adoption of renewable energy sources. Solar cells manufactured using this equipment contribute to reducing carbon emissions and mitigating environmental impact, supporting sustainability initiatives.

Reviews

There are no reviews yet.